The 2026 Guide to Selecting a High Quality Tempered Greenhouse Glass Supplier In China

QINHUANGDAO, HEBEI, CHINA, January 8, 2026 /EINPresswire.com/ -- As global agriculture continues to modernize, greenhouse construction is playing a more strategic role in food security, horticulture, and sustainable farming. Controlled-environment agriculture increasingly relies on durable, light-transmitting materials that can withstand climate stress while supporting crop growth efficiency. In this context, choosing a High Quality Tempered Greenhouse Glass Supplier In China has become an important consideration for greenhouse manufacturers, agricultural investors, and project developers planning installations in 2026 and beyond.

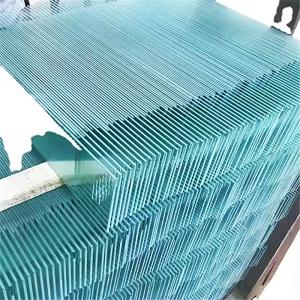

Tempered greenhouse glass is widely used for greenhouse roofs, walls, and façade systems due to its strength, thermal resistance, and stable light transmission. Compared with ordinary annealed glass, tempered glass undergoes controlled heat treatment, significantly improving its mechanical strength and safety performance. When breakage occurs, it shatters into small blunt fragments rather than sharp shards, reducing safety risks in agricultural environments. These characteristics make tempered greenhouse glass a preferred material for aluminum greenhouses, garden houses, and modern horticultural structures.

Industry Outlook: Greenhouse Construction in 2026 and Beyond

The greenhouse industry is undergoing steady growth driven by population increases, climate variability, and the demand for year-round crop production. Governments and private investors are supporting greenhouse projects that improve land-use efficiency and reduce water and pesticide consumption. As a result, material specifications are becoming more stringent, with greater attention paid to structural safety, optical performance, and lifecycle cost.

Glass suppliers serving this sector are expected to deliver consistent quality, precise dimensions, and reliable logistics. Thin yet strong glass panels, such as 3mm and 4mm tempered greenhouse glass, are increasingly used in aluminum greenhouse systems, where weight control and light transmission are both critical. At the same time, horticultural glass with optimized surface properties continues to be selected for applications focused on plant growth rather than architectural aesthetics.

Understanding Tempered Greenhouse Glass Options

Selecting the right greenhouse glass begins with understanding product specifications and application requirements. Tempered greenhouse glass is commonly available in thicknesses such as 3mm and 4mm, offering a balance between strength and light efficiency.

3mm toughened glass for aluminum greenhouse and garden house applications is designed for lightweight structures where maximum sunlight penetration is essential. Its reduced thickness allows higher light transmittance, which supports photosynthesis while maintaining adequate strength for standard wind and snow load conditions. This type of glass is often used in small to medium-sized greenhouses, garden houses, and modular greenhouse systems.

4mm toughened glass provides increased rigidity and impact resistance, making it suitable for larger greenhouse spans or regions with higher environmental loads. It is commonly installed in aluminum greenhouse frames where long-term durability and structural stability are priorities. This thickness is frequently selected for commercial greenhouses and agricultural projects that operate year-round.

In addition to tempered options, 3mm horticultural glass remains a widely used material in plant-focused greenhouse applications. Horticultural glass is designed to offer high light diffusion, which helps distribute sunlight evenly across crops. While not tempered, it is selected in projects where controlled environments and structural protection are already in place.

Key Criteria When Selecting a Supplier

When evaluating a tempered greenhouse glass supplier in China, several practical factors should be considered. Product consistency is essential, as dimensional accuracy directly affects installation efficiency and greenhouse sealing performance. Glass panels must fit precisely within aluminum framing systems to prevent air leakage, water ingress, and structural stress.

Processing capabilities are equally important. Suppliers that offer cut-to-size production, edge grinding, and uniform tempering can better support project-specific requirements. Clean, smooth edges reduce installation risks and help extend the service life of greenhouse structures.

Quality control practices also play a critical role. Stable tempering processes ensure consistent strength across glass batches, which is especially important for large greenhouse projects involving thousands of panels. Visual clarity, surface flatness, and low distortion contribute to predictable light transmission and crop performance.

LYD GLASS and Greenhouse Glass Manufacturing

LYD GLASS operates in Qinhuangdao, a coastal city in northern China known for its long-standing glass manufacturing industry. The company benefits from its proximity to Qinhuangdao Port and convenient access to Tianjin Port, providing efficient transportation solutions for international shipments. This geographical advantage supports timely delivery and helps manage logistics costs for overseas greenhouse projects.

Within the greenhouse glass segment, LYD GLASS supplies 3mm and 4mm toughened glass designed for aluminum greenhouses and garden houses. These products are manufactured to meet practical installation and performance requirements commonly specified by greenhouse system providers. The company also offers 3mm horticultural glass for applications where light diffusion and plant growth conditions are prioritized.。

Application Scenarios and Project Use

Tempered greenhouse glass supplied by LYD GLASS is used across a range of agricultural and horticultural applications. In commercial vegetable greenhouses, 4mm toughened glass panels are often installed in roof and sidewall systems to provide long-term stability and weather resistance. Their strength supports continuous operation under varying climate conditions.

For garden houses and small-scale greenhouses, 3mm tempered glass offers a lightweight solution that balances safety and transparency. These installations are commonly used in residential gardens, research facilities, and urban agriculture projects where space efficiency and visual openness are valued.

Horticultural glass applications include nurseries and flower cultivation facilities, where light diffusion helps reduce shadowing and promote uniform plant growth. Selecting the appropriate glass type for each application contributes to both structural performance and agricultural productivity.

Beyond traditional greenhouse applications, LYD GLASS also provides Tempered Glass for Veranda and Glazen schuifpanelen for controlled-environment structures. Tempered Glass for Veranda panels are used in greenhouse extension areas, garden terraces, and experimental veranda setups, offering enhanced durability, weather resistance, and high light transmission suitable for plant growth. Glazen schuifpanelen, or sliding glass panels, allow for flexible access, modular ventilation, and configurable layouts in both commercial and research greenhouses. These products expand the functional versatility of greenhouse projects, enabling designs that combine crop protection, ease of maintenance, and environmental control.

Logistics and Supply Chain Considerations

Glass transportation requires careful handling due to weight and fragility. Suppliers located near export ports can offer logistical advantages by reducing transit time and minimizing handling steps. LYD GLASS’s location allows for direct access to major shipping routes, supporting stable export schedules for greenhouse projects in Europe, North America, and other regions.

Reliable packaging, container loading, and export coordination are essential elements of supplier capability. These factors help ensure that glass panels arrive at project sites in good condition and ready for installation.

Long-Term Value and Supplier Reliability

Beyond product specifications, long-term supplier reliability is a key consideration. Greenhouse projects often involve phased construction, maintenance, or expansion. Working with a supplier capable of consistent production over time helps maintain uniformity across installations.

By focusing on standardized production, controlled processing, and practical service support, suppliers can contribute to smoother project execution and reduced operational risks. These attributes are increasingly valued as greenhouse investments grow in scale and complexity.

Conclusion

Selecting a tempered greenhouse glass supplier in 2026 requires careful evaluation of product quality, processing capability, logistics support, and industry experience. Tempered greenhouse glass, particularly in 3mm and 4mm thicknesses, continues to play a central role in modern greenhouse construction due to its safety, strength, and light transmission properties.

LYD GLASS contributes to this sector through the supply of tempered and horticultural greenhouse glass products designed for aluminum greenhouse and garden house systems. Supported by its manufacturing base in Qinhuangdao and access to major export ports, the company aligns with the practical needs of global greenhouse projects.

For more information, please visit https://www.lydglass.com/.

Tempered greenhouse glass is widely used for greenhouse roofs, walls, and façade systems due to its strength, thermal resistance, and stable light transmission. Compared with ordinary annealed glass, tempered glass undergoes controlled heat treatment, significantly improving its mechanical strength and safety performance. When breakage occurs, it shatters into small blunt fragments rather than sharp shards, reducing safety risks in agricultural environments. These characteristics make tempered greenhouse glass a preferred material for aluminum greenhouses, garden houses, and modern horticultural structures.

Industry Outlook: Greenhouse Construction in 2026 and Beyond

The greenhouse industry is undergoing steady growth driven by population increases, climate variability, and the demand for year-round crop production. Governments and private investors are supporting greenhouse projects that improve land-use efficiency and reduce water and pesticide consumption. As a result, material specifications are becoming more stringent, with greater attention paid to structural safety, optical performance, and lifecycle cost.

Glass suppliers serving this sector are expected to deliver consistent quality, precise dimensions, and reliable logistics. Thin yet strong glass panels, such as 3mm and 4mm tempered greenhouse glass, are increasingly used in aluminum greenhouse systems, where weight control and light transmission are both critical. At the same time, horticultural glass with optimized surface properties continues to be selected for applications focused on plant growth rather than architectural aesthetics.

Understanding Tempered Greenhouse Glass Options

Selecting the right greenhouse glass begins with understanding product specifications and application requirements. Tempered greenhouse glass is commonly available in thicknesses such as 3mm and 4mm, offering a balance between strength and light efficiency.

3mm toughened glass for aluminum greenhouse and garden house applications is designed for lightweight structures where maximum sunlight penetration is essential. Its reduced thickness allows higher light transmittance, which supports photosynthesis while maintaining adequate strength for standard wind and snow load conditions. This type of glass is often used in small to medium-sized greenhouses, garden houses, and modular greenhouse systems.

4mm toughened glass provides increased rigidity and impact resistance, making it suitable for larger greenhouse spans or regions with higher environmental loads. It is commonly installed in aluminum greenhouse frames where long-term durability and structural stability are priorities. This thickness is frequently selected for commercial greenhouses and agricultural projects that operate year-round.

In addition to tempered options, 3mm horticultural glass remains a widely used material in plant-focused greenhouse applications. Horticultural glass is designed to offer high light diffusion, which helps distribute sunlight evenly across crops. While not tempered, it is selected in projects where controlled environments and structural protection are already in place.

Key Criteria When Selecting a Supplier

When evaluating a tempered greenhouse glass supplier in China, several practical factors should be considered. Product consistency is essential, as dimensional accuracy directly affects installation efficiency and greenhouse sealing performance. Glass panels must fit precisely within aluminum framing systems to prevent air leakage, water ingress, and structural stress.

Processing capabilities are equally important. Suppliers that offer cut-to-size production, edge grinding, and uniform tempering can better support project-specific requirements. Clean, smooth edges reduce installation risks and help extend the service life of greenhouse structures.

Quality control practices also play a critical role. Stable tempering processes ensure consistent strength across glass batches, which is especially important for large greenhouse projects involving thousands of panels. Visual clarity, surface flatness, and low distortion contribute to predictable light transmission and crop performance.

LYD GLASS and Greenhouse Glass Manufacturing

LYD GLASS operates in Qinhuangdao, a coastal city in northern China known for its long-standing glass manufacturing industry. The company benefits from its proximity to Qinhuangdao Port and convenient access to Tianjin Port, providing efficient transportation solutions for international shipments. This geographical advantage supports timely delivery and helps manage logistics costs for overseas greenhouse projects.

Within the greenhouse glass segment, LYD GLASS supplies 3mm and 4mm toughened glass designed for aluminum greenhouses and garden houses. These products are manufactured to meet practical installation and performance requirements commonly specified by greenhouse system providers. The company also offers 3mm horticultural glass for applications where light diffusion and plant growth conditions are prioritized.。

Application Scenarios and Project Use

Tempered greenhouse glass supplied by LYD GLASS is used across a range of agricultural and horticultural applications. In commercial vegetable greenhouses, 4mm toughened glass panels are often installed in roof and sidewall systems to provide long-term stability and weather resistance. Their strength supports continuous operation under varying climate conditions.

For garden houses and small-scale greenhouses, 3mm tempered glass offers a lightweight solution that balances safety and transparency. These installations are commonly used in residential gardens, research facilities, and urban agriculture projects where space efficiency and visual openness are valued.

Horticultural glass applications include nurseries and flower cultivation facilities, where light diffusion helps reduce shadowing and promote uniform plant growth. Selecting the appropriate glass type for each application contributes to both structural performance and agricultural productivity.

Beyond traditional greenhouse applications, LYD GLASS also provides Tempered Glass for Veranda and Glazen schuifpanelen for controlled-environment structures. Tempered Glass for Veranda panels are used in greenhouse extension areas, garden terraces, and experimental veranda setups, offering enhanced durability, weather resistance, and high light transmission suitable for plant growth. Glazen schuifpanelen, or sliding glass panels, allow for flexible access, modular ventilation, and configurable layouts in both commercial and research greenhouses. These products expand the functional versatility of greenhouse projects, enabling designs that combine crop protection, ease of maintenance, and environmental control.

Logistics and Supply Chain Considerations

Glass transportation requires careful handling due to weight and fragility. Suppliers located near export ports can offer logistical advantages by reducing transit time and minimizing handling steps. LYD GLASS’s location allows for direct access to major shipping routes, supporting stable export schedules for greenhouse projects in Europe, North America, and other regions.

Reliable packaging, container loading, and export coordination are essential elements of supplier capability. These factors help ensure that glass panels arrive at project sites in good condition and ready for installation.

Long-Term Value and Supplier Reliability

Beyond product specifications, long-term supplier reliability is a key consideration. Greenhouse projects often involve phased construction, maintenance, or expansion. Working with a supplier capable of consistent production over time helps maintain uniformity across installations.

By focusing on standardized production, controlled processing, and practical service support, suppliers can contribute to smoother project execution and reduced operational risks. These attributes are increasingly valued as greenhouse investments grow in scale and complexity.

Conclusion

Selecting a tempered greenhouse glass supplier in 2026 requires careful evaluation of product quality, processing capability, logistics support, and industry experience. Tempered greenhouse glass, particularly in 3mm and 4mm thicknesses, continues to play a central role in modern greenhouse construction due to its safety, strength, and light transmission properties.

LYD GLASS contributes to this sector through the supply of tempered and horticultural greenhouse glass products designed for aluminum greenhouse and garden house systems. Supported by its manufacturing base in Qinhuangdao and access to major export ports, the company aligns with the practical needs of global greenhouse projects.

For more information, please visit https://www.lydglass.com/.

QinHuangDao LianYiDing Glass CO.,LTD

QinHuangDao LianYiDing Glass CO.,LTD

+ +86 13315367306

info@dingsen-industry.com

Visit us on social media:

Instagram

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.